Hemp Nation Grow Room Project 2024/5

Introduction

The Hemp Nation Indoor Grow Project was established to respond to the increasing global demand for CBD and hemp-based products by fostering accessible, high-quality, small-scale farming models in Eswatini. Hemp Nation’s approach centers on guaranteeing the quality of the seeds used and ensuring that each strain’s key metrics—such as cannabinoid content and plant vigor—can be produced and reliably tested. The vision is to create a transparent process where local farmers are empowered to certify their crops and maintain a standard of excellence, enabling them to build trust with future customers and markets.

The Hemp Nation Indoor Grow Project was established to respond to the increasing global demand for CBD and hemp-based products by fostering accessible, high-quality, small-scale farming models in Eswatini. Hemp Nation’s approach centers on guaranteeing the quality of the seeds used and ensuring that each strain’s key metrics—such as cannabinoid content and plant vigor—can be produced and reliably tested. The vision is to create a transparent process where local farmers are empowered to certify their crops and maintain a standard of excellence, enabling them to build trust with future customers and markets.

Since August 2023, Hemp Nation and Mgadlela Farm have collaborated to construct a practical and affordable indoor grow room, designed to support healthy mother plants and successful clone production. The facility is both a worksite and a learning space, prioritizing teamwork and hands-on experimentation to refine cultivation methods and address real-world challenges. Continuous research—shared among partners and prospective growers—drives the project forward, ensuring that both technology and skills are accessible to all participants.

Hemp Nation is committed to building a culture of teamwork and applied research for lasting sector growth in Eswatini.

Strategic Objectives

To support long-term cultivation capacity and knowledge transfer in Eswatini, the project focuses on the following development goals:

- Construct a permanent indoor grow facility, for controlled cultivation and high-quality mother plants.

- Expand agricultural infrastructure, by extending existing farm buildings, improving workflow and production capacity.

- Build advanced horticultural knowledge, focused on maintaining healthy plants in a fully enclosed growing environment, including climate control, nutrient management, and pest prevention.

- Develop and refine cloning expertise, enabling consistent production of healthy, uniform clones that can be successfully transitioned from indoor growth to outdoor fields.

- Establish a reliable supply chain for cuttings and develop a genetics preservation and propagation system for consistent strain performance and stable cannabinoid profiles, with a long-term plan to introduce and maintain pure CBD genetics.

These objectives collectively lay the foundation for a resilient, accessible, small-scale hemp production model that prioritises transparency, consistency, and knowledge-sharing while empowering local growers to participate meaningfully in the expanding global hemp economy.

The team sourced a suitable grow light from a local supplier in Matsapha, prioritizing affordability and reliability for the indoor space. Together, we assembled and installed the lighting and sturdy tables to support the cultivation and care of our mother plants.

To maintain healthy growing conditions, ventilation equipment, fans, and thermometers were fitted to monitor and adjust the air quality and temperature as needed.

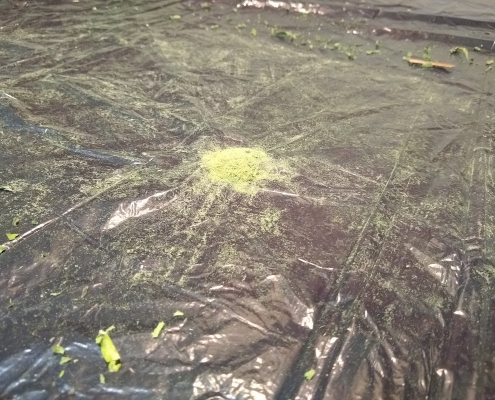

The tables—custom-built for the project—were covered in plastic sheeting to prevent water damage and then sprayed white to improve light reflection, maximizing growth potential in the limited space.

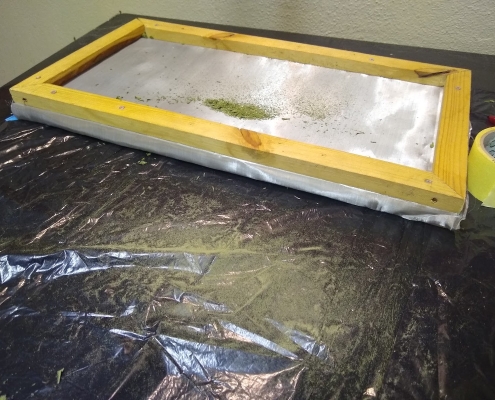

For optimal light reflection and water runoff control, a grow tray lined with aluminium foil was installed.

[13th Oct & 2nd Oct – Cuttings]

The first clone arrived in the grow room on 7th August 2024, chosen to become a mother plant. This was a Buddha Cheese variety, known for its distinctive aroma and reliable growth characteristics. The plant grew well under the single grow light, adapting steadily over the first seven weeks.

During this period, we learned how to train and trim the plant effectively while it was still under the light, taking advantage of the guaranteed longer vegetative phase indoors. This hands-on experience was crucial, helping us understand how to encourage strong branching and prepare healthy plants for future cloning cycles.

[23rd, 30th Oct] Mother Plant

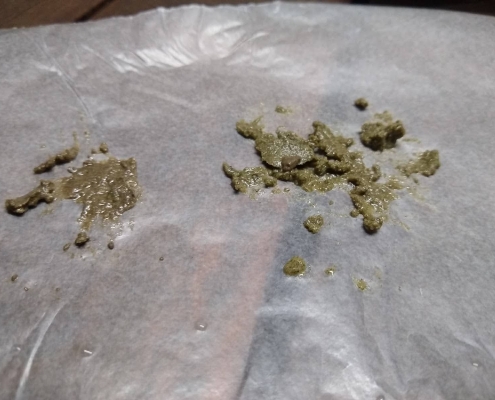

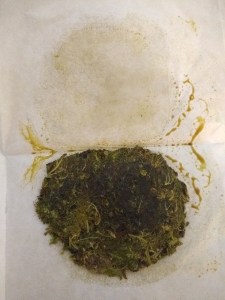

The first cuttings were taken on 1st October once the mother plant had grown large enough to be trimmed and trained. Over the following weeks, approximately 30 cuttings were taken, and by 23rd October, five clones had successfully rooted and were transplanted individually into soil grow bags.

[30 Oct] Cutting

The mother plant continues to thrive, producing new shoots that serve as the source for ongoing cuttings. This phase has been valuable for learning how to manage plant training under the grow light, extending the vegetative period and promoting healthier growth for future clones.

The final phase of the project remains to be completed—transferring the grown clones outdoors into the field to flower. This will open the next stage of growth research, helping refine techniques for outdoor cultivation and maximizing yield.

Germination and Growth Research

In addition to maintaining a mother plant and producing clones, seeds have also been germinated directly in the grow room and allowed to develop. This was done to evaluate how quickly and efficiently local seeds could be started and grown through the early stages before being moved outdoors. It also maximises usage of the available light patch and table space, both from the grow light and through the clear roof sheets.

Throughout this process, electricity usage has been carefully monitored. Currently, only the grow light and two fans are running, with a monthly cost of approximately E200 emalangeni. This cost is considered relatively low compared to anticipated future electricity expenses, which are expected to rise as more lighting and ventilation equipment are added.

Limitations

Some limitations have become apparent during the project. While the grow room itself is large enough for current needs, the single installed light only covers about 1.5 square meters with sufficient intensity for good plant growth. This is not enough to fully support both the mother plants and the expanding canopy of clones, so additional lighting will be required to meet future demands.

Changes to the original build plans meant the room’s interior could not be finished as intended. The walls and floor have not yet been painted with a reflective colour, which likely reduces light efficiency. We are exploring options such as reflective paint or alternative materials to improve the reflectivity of the internal surfaces and maximise light use.

With the arrival of summer, temperatures inside the grow room have risen above ideal levels. To address this, an extractor fan was installed in the wall on 7th November. Going forward, temperature changes will be closely monitored and further ventilation improvements, such as installing ventilation blocks, may be added to maintain a stable and healthy environment for the plants.

Conclusions

As of October 2025, the project can be considered a success so far. The grow room structure is up and watertight, with healthy plants growing inside. The system has been operational for two months, during which time two batches of clones have been taken and are growing well. The combination of the grow light and clear roof sheets has proven effective, harnessing natural sunlight during the day to produce strong plant growth.

However, the actual build cost exceeded initial estimates, leading to delays. Challenges such as transport logistics, distance from town, and limited availability of local artisans also contributed to a slower-than-expected timeline. The grow room itself is complete, but budget constraints have delayed completion of the larger structure. Future work will focus on finishing the adjacent space (planned as a kitchen), installing windows, doors, a patio roof, and running water.

The most significant achievement has been the increase in the farmer’s horticultural knowledge, particularly around controlled-environment growing systems. This new approach will enable more consistent results and reduce dependency on seed supply. Using clones allows for uniform genetics and a reliable production schedule once the system is fully operational. Mgadlela Farm has reached new levels of understanding and accelerated learning, moving into controlled cultivation for the first time.

Overall, the educational process has been highly successful, with hands-on experience proving very effective for developing skills in plant training and understanding the effects of light cycles on growth. While the project is behind schedule, it is progressing steadily toward its goals and educational objectives.